Contura II Rail Shower with Overhead - Chrome

無法載入取貨服務供應情況

- Description

- What is PVD

The Caroma Contura II Rail Shower in Chrome is part of the new collection that is both sculptural and luxurious. Designed with a full suite of products, the new Contura II range of tapware and showers are available in Chrome, PVD Brushed Nickel, PVD Brushed Brass, Matte Black and the new PVD Brushed Bronze.

Create a designer bathroom that is relaxing and spa like using the natural luxury and subtle indulgence of the Contura II bathroom range.

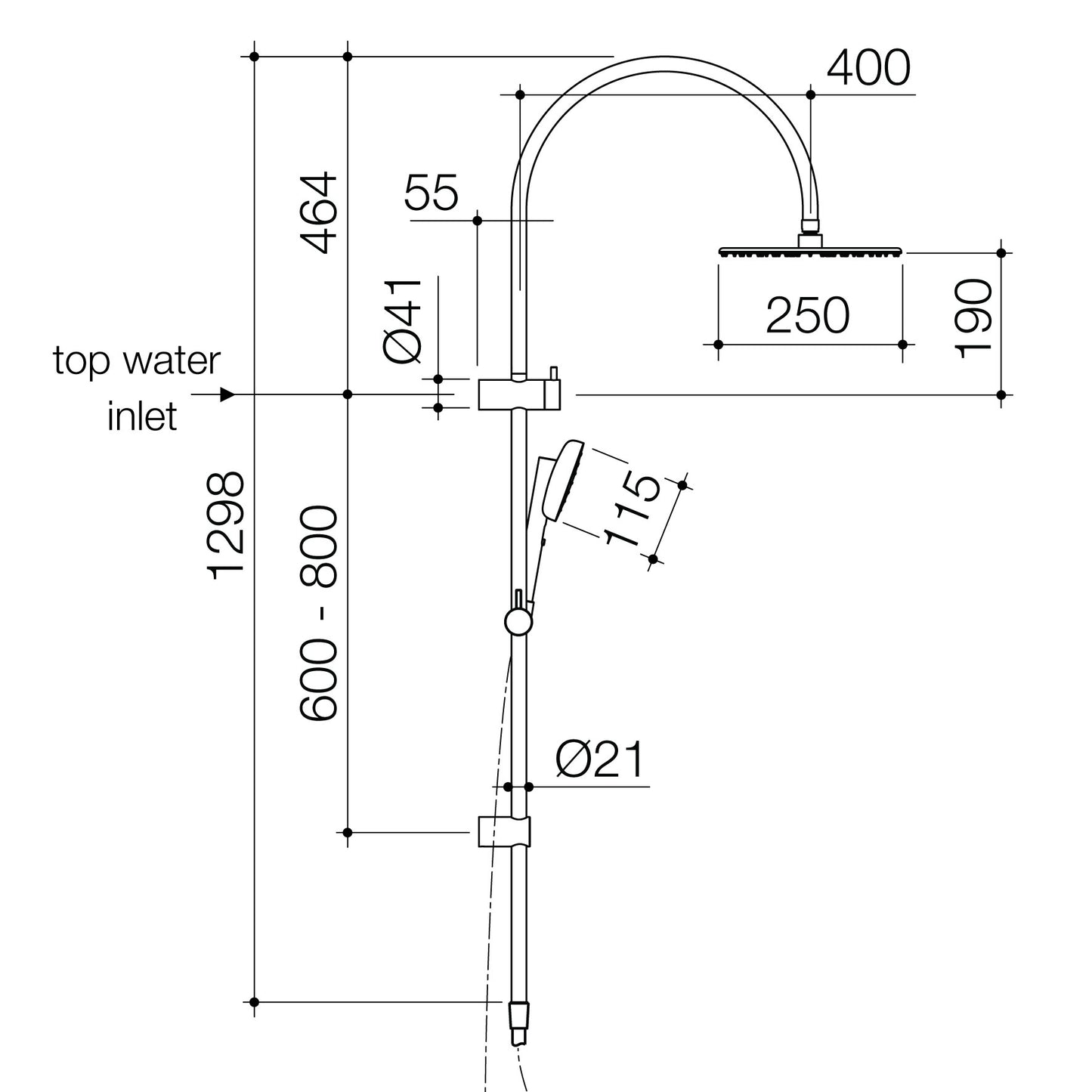

Caroma Contura II Rail Shower with Overhead SKU: 849080C4A

- VJet® techology in the hand shower for the ultimate showering experience that puts you in control

- Contains premium quality dual check valves, designed to prevent backflow, effective against back pressure and back siphonage

- PVD Finishes available for striking design & durability. Available in chrome, matte black, brushed bronze, brushed brass and brushed nickel

- Easy slide rail to adjust height

- Caroma showers are 100% leak tested

- Durable brass construction

- Australian designed and engineered

- Caroma tapware is 100% leak tested

- Overhead WELS 4 Rated, 7.5L/min Hand Shower WELS 4 Rated, 7.5L/min

- Up to 20 year product replacement warranty - see here

The Caroma Contura II product range suits any home and now features a range of colour finishes across tapware, showers and accessories that can be tailored to your personal style.

Available in:

Chrome

Brushed Brass

Brushed Nickel

Brushed Bronze

Matte Black

PVD stands for “Physical Vapor Deposition”, a coating technique used to deposit a thin film (a few microns thick) on the surface of bathroom products such as tapware, showers and accessories, to provide superior durability and resistance to abrasions, scratches and corrosion.

It is a vacuum deposition ionic energy process that provides a uniform deposit, strong adhesion and avoids the large edge build-ups that are common with electroplated coatings. This technique is environmentally friendly, as the process does not create any of the hazardous waste or toxic fumes.

Caroma PVD creates brilliant decorative metallic finishes that are durable with excellent wear. Its fine, even application is not only strong but also allows the beauty of the machined finish to shine through. It is an extremely durable and a tough wearing coating that will stay on the product and last for longer.

Due to the complexities involved in this process and the natural variations in the base materials, subtle variations in finishes are expected. Additional factors such as brush direction, installation position and even ambient lighting can also affect the visible appearance of the finished product.

Share